The low and linear low density produced polyethylene is primarily used for film packaging and for electrical insulation while HDPE is blow and injection molded to make containers for household chemicals, drums for industrial packaging and extruded as piping. Polyethylene can also be slit or spun into synthetic fibers or modified to take on the elastic properties of a rubber to create custom Polyethylene molded parts and extrusions. CFS has the extensive experience in taking part designs and optimizing them in functionality, cost and the Polyethylene plastic injection molding process.

Common Polyethylene parts include:

- Seals

- Tubing

- Shims

- Weather-strips

- Guards

- Cord

- Bindings

- Delrin

- Step treads

- Chock blocks

Custom Polyethylene Parts:

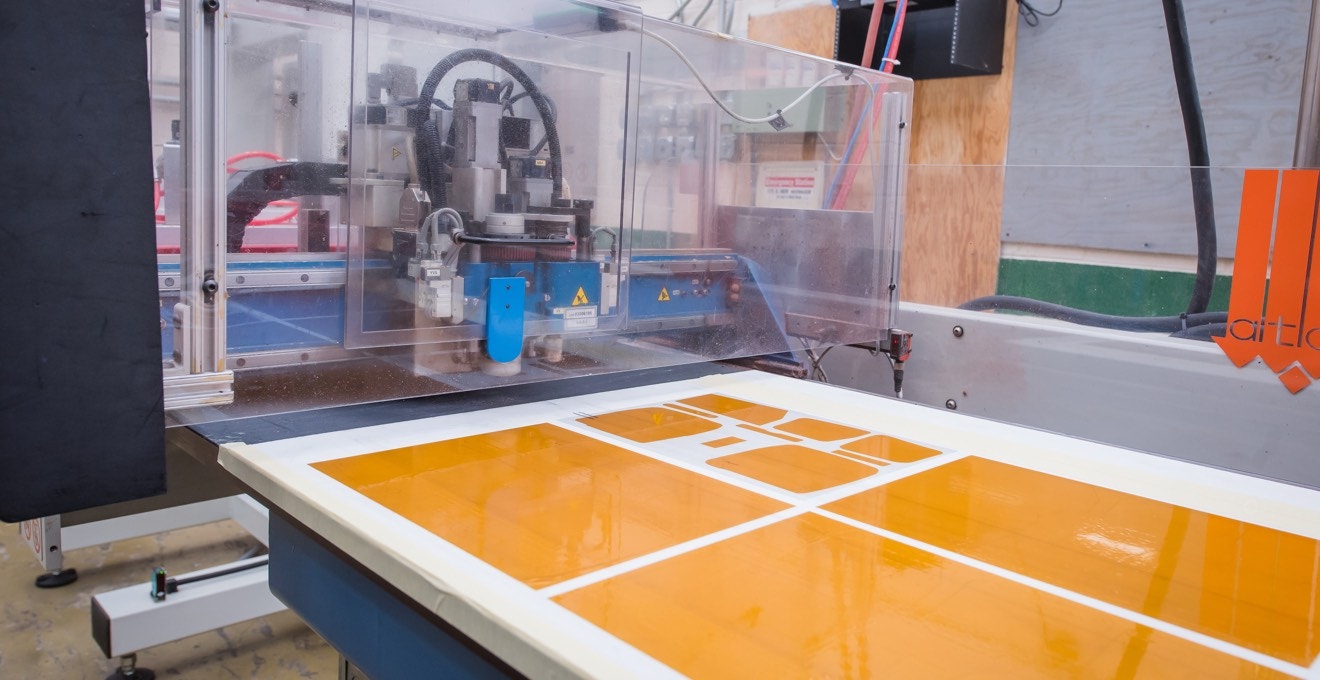

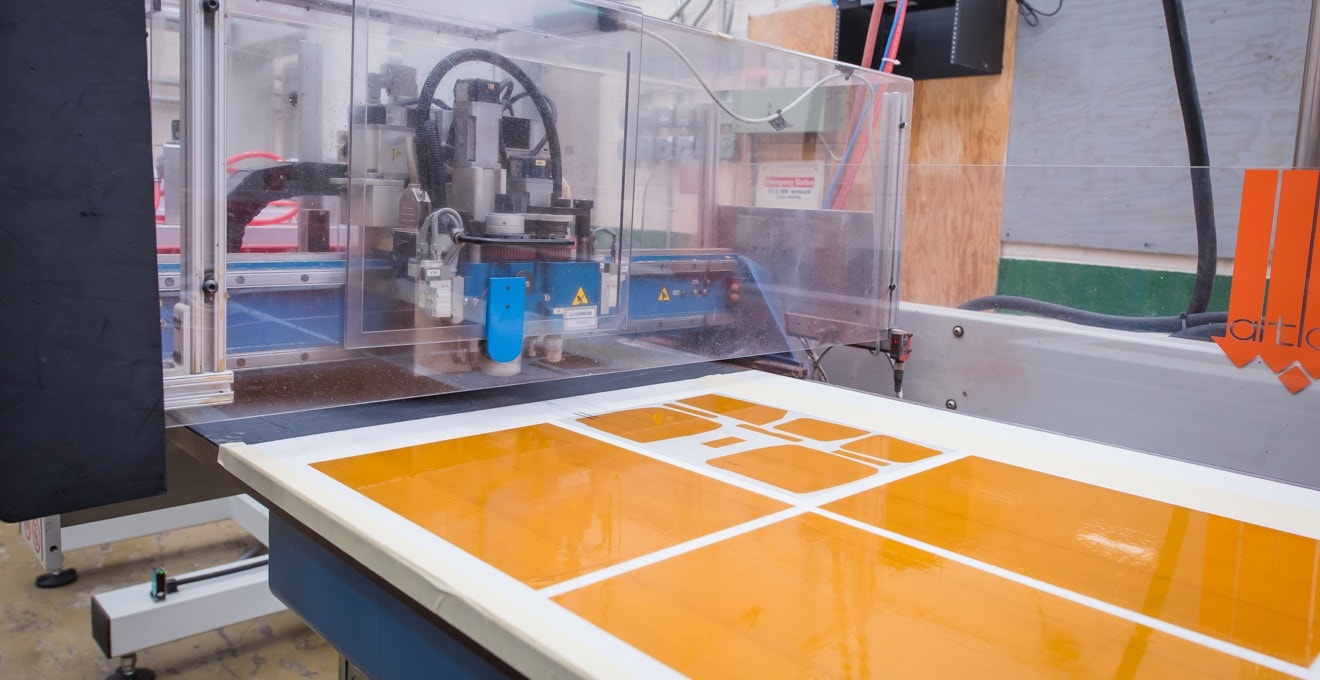

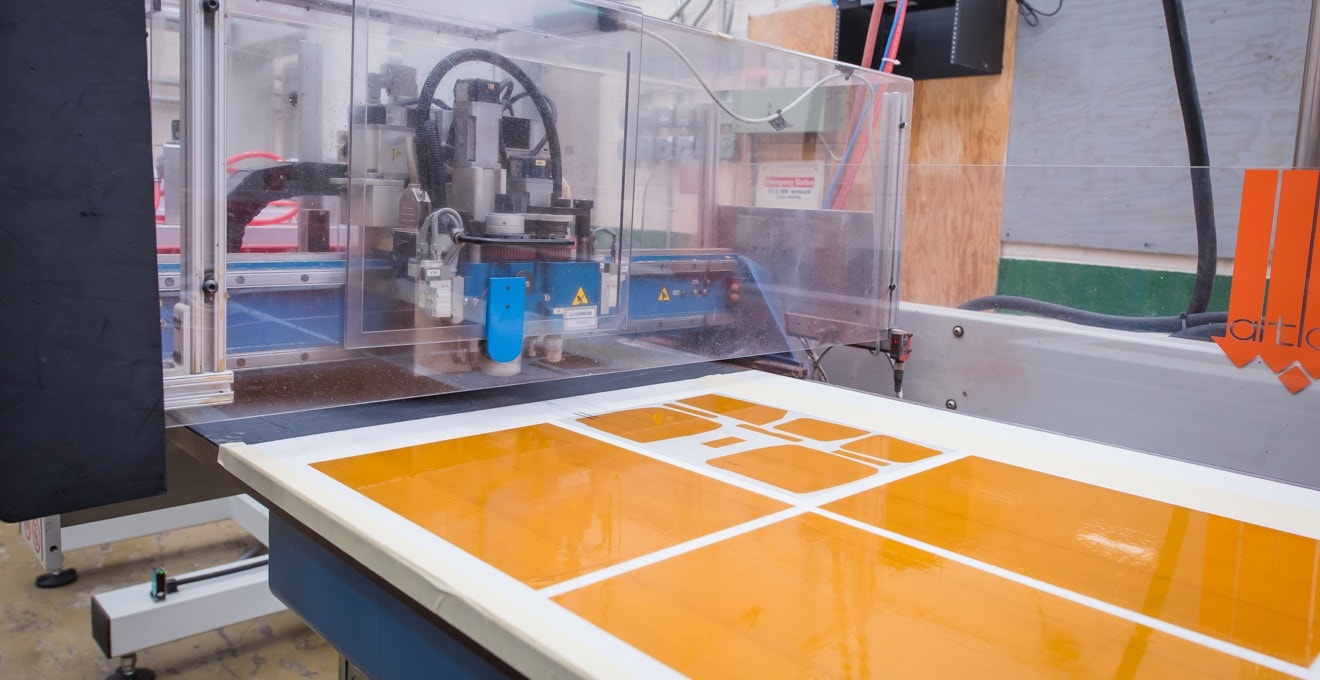

Our team can deliver high-quality Polyethylene parts to meet your specifications using proper custom molding and extrusion machining.

CFS uses custom molding and extruding machinery to bring the best in quality custom Polyethylene part solutions. Common custom Polyethylene parts applications include:

- Plumbing

- Marine

- Furniture

- Construction

Polyethylene Capabilities

Our team at CFS has the expertise and skills to provide custom molding and extrusions to meet your Polyethylene molded part needs. Whether you need help prototyping and designing a part or already have a working blueprint, we ensure that you will have a quality finished product on time.

To learn more about our custom extrusions and molding using Polyethylene, please contact us today.