Main image Click to view image in fullscreen

![]()

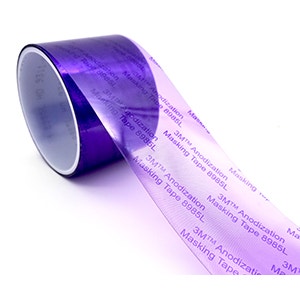

3M 8985L Chromic Acid Anodizing Tape

Sku:8985L

Starting at: $18.2401

Starting at:

Starting at: $18.2401

Starting at:

Rolls

Volume Pricing Discounts

Need Help Finding the Right Part?

Masking Product Finder - Get the right size!

Cross Reference Tool - Find equivalent CFS parts!

Product Details

3M™ Anodization Masking Tape 8985L is a purple printed polyester tape with a rubber adhesive and non-silicone release liner. Designed specifically for masking parts against chromic anodization bath processes. A strong backing provides excellent abrasion, tear, scratch, puncture and moisture resistance to help protect surfaces.

Product Features

- Operates at temperatures up to 200°F/93°C

- The purple transluscent polyester backing allows for visual inspection without tape removal

- Provides good initial tack and holding strength

- Rubber adhesive is specifically formulated to resist the harshest of chemical bath chemistries

- Provides clean removal after anodization process

- Non-silicone adhesive allows this product to be used on many parts where subsequent painting or bonding is necessary

- Non-silicone liner allows for die cuts

Construction

- 3.9 Mil Total Thickness

- Roll Length - 72 yards

Recommended Applications

- For masking parts during chromic anodization bath processess

Specifications

- Tensile Strength (lb/in) - 70

- Elongation (%) - 131

- Steel Adhesion (oz/in) - 23

Material Specifications