What is Contract Converting?

Converting involves various techniques such as cutting, slitting, rewinding, laminating, coating, or printing to modify the characteristics or properties of the raw materials. Custom converting is often used in industries such as packaging, automotive, electronics, and healthcare, where specific requirements need to be met for the end products.

Contract converting, also known as toll converting, is a strategic method employed by manufacturers to outsource their converting requirements to a specialized third-party provider. By entrusting CFS with the task of converting materials on your behalf, you can optimize your operations and streamline your production processes. In many cases, our customers supply the raw materials that need to be converted.

What it means to be a 3M Preferred Converter

3M only recognizes elite converting companies that consistently exceeded others in quality, capabilities, experience and customer service with this designation. CFS is proud to be among this group. There’s little question that 3M is one of the most recognizable, trusted brands in the world. 3M’s lines of tapes are ideal for paint masking, bonding, surface protection and pressure sensitive adhesion. 3M tapes provide excellent coverage and precision for even the toughest of jobs.

Specialized Converting Services from CFS

CFS offers contract converting services for customers who do not need further die cutting of their material – we are happy to work with customer supplied material.

Slitting – Rewinding – Laminating

The addition of the Elite Cameron rewind slitter has already proven to be a game changer for our customers. We now can convert master logs of tape into “mults” that have been laminated in-line, at speeds up to 1,000 ft/min. Previously we were limited to rewind slitting at a fraction of that speed and laminating in a second step. For one customer, this allowed us to produce a new design at a price point within their budget due to the labor and time savings. Master logs can weigh as much as 3,000 lbs with a 48” diameter. Lamination unwind max diameter 16”. Maximum unwind diameter 31.5”. Score and razor slitting.

Single knife (log) slitting – this is the traditional method of taking a longer roll of material and creating smaller rolls. We have multiple slitting machines that can accommodate films, adhesive tapes and foams with diameters to 24”, log widths to 62”, roll slitting as narrow was 0.062”.

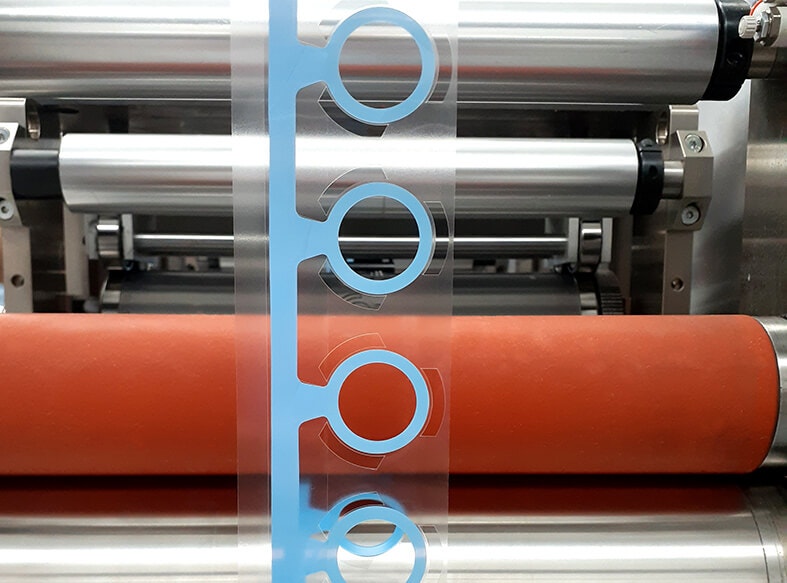

Narrow web rewind slitting - The Siat narrow web rewind slitter is a specialty machine with a very unique use. Certain tapes, like 3M 468MP (a transfer tape) are notoriously difficult to slit using standard single-knife operations. The lack of carrier material causes the tape to “roll” onto subsequent layers, making them challenging to unwind. The Siat can unwind the master roll, slit with razors and precisely rewind onto new cores. This process is slower than traditional methods but provides extremely precise rewind slitting. Maximum width of master log 12” with roll diameter to 18”. Razor slitting to ¼”.

Adhesive laminating - Pressure-sensitive adhesives, double-coated adhesives and transfer tapes can be laminated to virtually any material, accommodating up to five individual materials together in one pass. Complex solutions include zone coating & island placement.

Die Cutting

From industrial adhesive tapes to thick gasket foams, CFS can cut most non-metallic materials – from 0.002” in diameter to 60”, thicknesses to 5”. We utilize a variety of die cutting methods to achieve the best product for our customers at the best price.:

- Laser Die Cutting – Tolerance to +/- 0.001”, thickness to 0.375” and 13” diameter

- Precision Rotary Die Cutting – Tolerance to +/- 0.005”, thickness to 0.25” and 13” diameter

- Digital Knife/flash cutting – Tolerance to +/- 0.005”, thickness to 5” and 60” diameter

- Flatbed die cutting – Tolerance to +/- 0.005”, thickness to 1.5” and 20” diameter

- Steel rule die cutting – Tolerances to 0.10”, thickness to 1.5”, and 29” diameter

Each process has specific advantages – dictated by volume, tolerance or material type. CFS has product & design engineers on site to make sure the best process is utilized. Solutions include:

- Kiss cutting

- Butt Cutting

- Pull Tabs

- Scoring

- Sheeting

- Split Liners

- Zoned Adhesive

- Creasing

- Kitting

- Perforating

- Island Placement

- Multi-layer lamination

Converted Materials

Pressure Sensitive Tapes (e.g., double-coated tape, cloth tape, magnetic materials, metallic tape, industrial PET tapes, VHB tapes and many others). These materials are used in a variety of applications depending on their composition and construction. For example, double-coated tape is used to attach parts to automobiles or POP displays, while filament tape is used to reinforce and close packaging containers.

Foam materials can be die cut into various shapes and sizes for use in packaging, sealing, protection and insulation applications.

Paper and chipboard is used for the production of countless parts and products across different industries and sectors. Typical paper packaging products include packaging spacers, dividers and masking.

Plastic films (e.g., polyester, polyethylene, polypropylene, PVC, and UHMW in film, sheet, and roll form). These are available with or without adhesive. Typical operations include cutting, laminating, pre-masking, rewinding, sheeting, and slitting.

Converting services can be used by a wide variety of industries, including:

- Manufacturing

- Packaging

- Printing

- Automotive

- Aerospace

- Medical

- Electronics

- Food and beverage

- Consumer goods