News & Events

- December 05, 2023

Q: I’m investigating the cost differences in customized masking versus off-the-shelf standard solutions. I’m trying to get a holistic idea of costs over time. Can you offer some perspective?

A: “It’s so expensive.” Far and away, this is the response...

- February 21, 2023

Powder and electro-coating small parts can be tricky. Since each part must be individually hung for full coverage and grounding, parts can easily be pushed off during a wash cycle or floated off during immersion. A customer came to us for solutions when they were...

- February 07, 2023

Christmas 2022 brought the final production machine to the floor of the Custom Fabricating & Supplies expansion (CFS, Franklin, WI) – a 50 ton compression/transfer molding press. “The past 3 years have highlighted many challenges in the supply chain. The number...

- January 10, 2023

After experiencing tremendous growth in 2021 we were bursting at the seams. Navigating supply chain delays and shortages throughout the ‘22 expansion, the final machine arrived just in time for Christmas. When the dust settled we gained 32,000 square feet in our...

- August 09, 2021

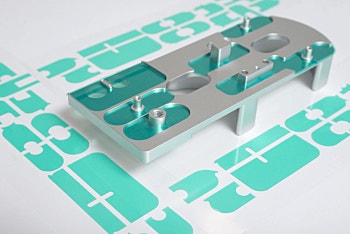

On the surface it sounds pretty simple – make a tape die cut with an island in the middle that is non-adhesive. Even looking at the final product does not reveal the complexities of creating precise island placement on tapes. Recently CFS had the opportunity to...

- July 12, 2021

As a 3M Preferred Converter, CFS has the opportunity to work on very challenging projects which require an extensive knowledge of the intricacies and eccentricities of die cutting VHB and high-performance foam tapes. The properties of these tapes which make them...

- May 06, 2021

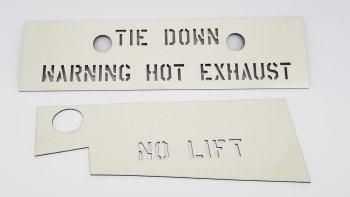

Chemical Agent Resistant Coating (CARC) is the organic topcoat used on the majority of the armed service’ combat vehicles, aircraft, ordinance and tactical equipment. Its unique formulation allows coated vehicles to be decontaminated in the event of exposure to...

- February 24, 2021

Powder coating is a dry finishing process that has become extremely popular since its introduction in North America in the 1960s. Representing over 15% of the total industrial finishing market, the global powder coatings market is expected to reach $16.55B...

- January 28, 2021

A large equipment manufacturer was struggling to trace masking issues through their paint line. They asked CFS if we would be able to produce kit die cuts with QR codes that could be scanned at each step in the paint process. With our new Domino printer installed...

- December 21, 2020

Q. We are having issues with plug loss and leakage during coating. Rework is expensive – how can we mitigate this?

A. Excellent question! There are many factors that influence plug loss or leakage. Here are some recommendations for avoiding plug...