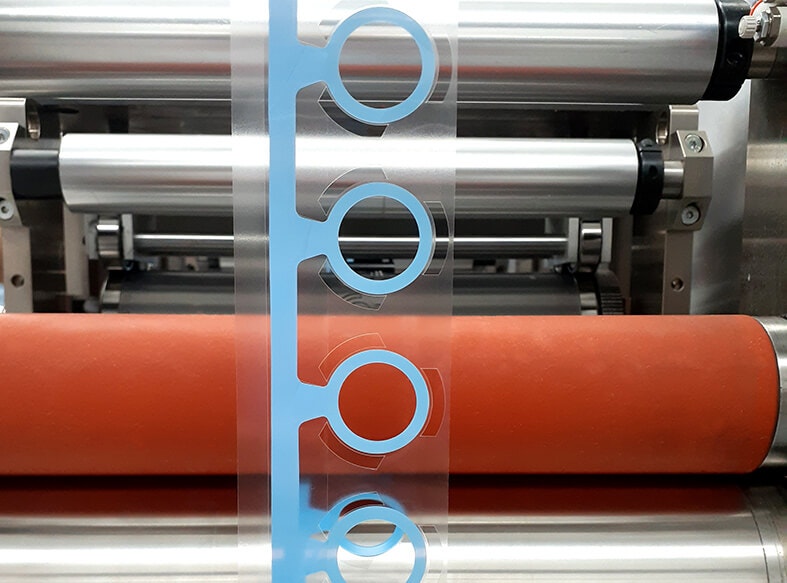

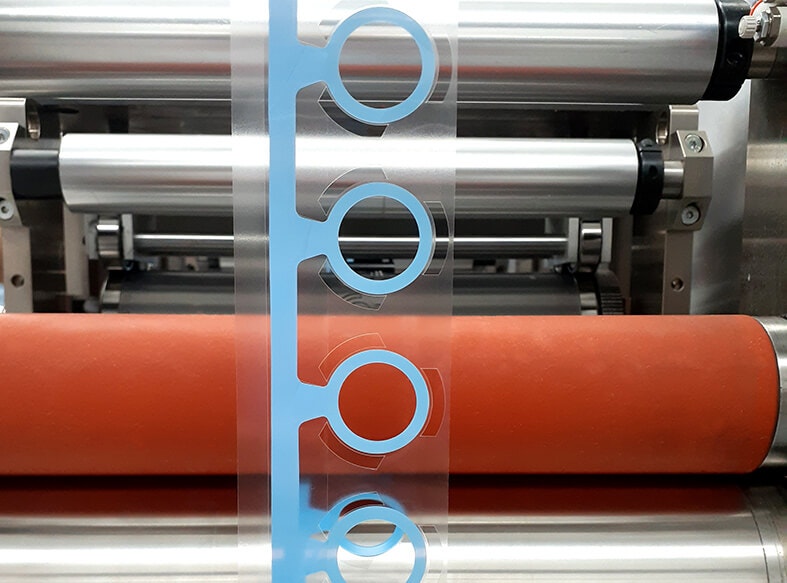

Precision die cutting in a controlled environment

Our ISO 7 clean room features temperature and humidity control in a permanent, hardwall facility. State of the art technology offers die cutting for web widths up to 13” with tight tolerances as small as 50 microns. Clean room manufacturing is a niche market generally performed by companies that are geared for large volumes – and extended lead times. CFS is known for tackling the tough projects with tight timelines. As a company that is agile and accustomed to working with smaller, custom projects, CFS can produce your clean room products in weeks, not months.

Specialty converting service in a clean room environment include:

As a 3M™ Preferred Converter, we have access to their full line of medical and industrial tapes. For more information on our custom clean room manufacturing services or to speak with one of our knowledgeable professionals please feel free to Contact Us or complete our online Request A Quote form.

- Kiss Cutting

- Sheeting

- Butt Cuts

- Split liner

- Perforating

- Pull Tabs

- Zoned Adhesive

- Island Placement

- Kitting

- Multi-layer laminations

Wearable Technologies

- Insulin delivery pump securement adhesive

- Health monitoring device interface components (electrodes, activity trackers, EKG monitors)

- Glucose monitoring securement adhesive

- Fixation of wearable rehabilitation devices

Health & Beauty

- Cosmetic Accessoriese

- Anti-wrinkle pads

- Kinesiology tape

- Orthopedic pads

- Fashion tape

- Scar treatments

Medical Grade Materials

- Pressure sensitive adhesives and tapes

- Skin-contact, gentle release tapes

- Polyethylene foams

- PET non-woven fabrics

- Filtration mesh

- Single and double coated PU films

Electronics

- Polyimide and conformal coating tapes

- Multilayer components

- EMI shielding

- Protection tapes

- Thermal management components