EV Battery Die Cut Solutions

Side image CFS is a leader in the converter market, leveraging advanced technologies to provide die cut solutions for electric vehicle (EV) battery components. As a 3M Preferred Converter holding ISO 9001:2015 certification, our systems are set up to meet the strict demands of the automotive industry. Contact CFS to learn how we can provide rapid turnaround on material samples and prototypes and our design assistance and consultation services.

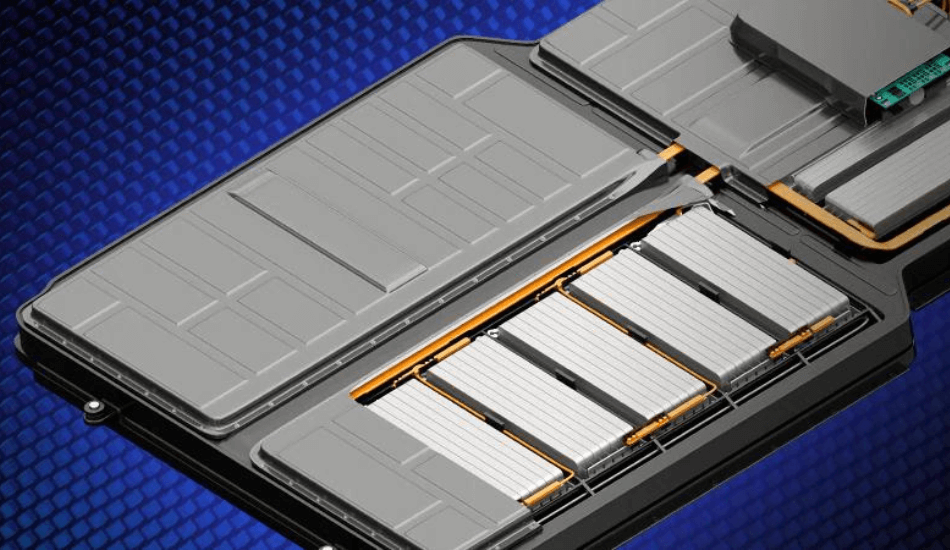

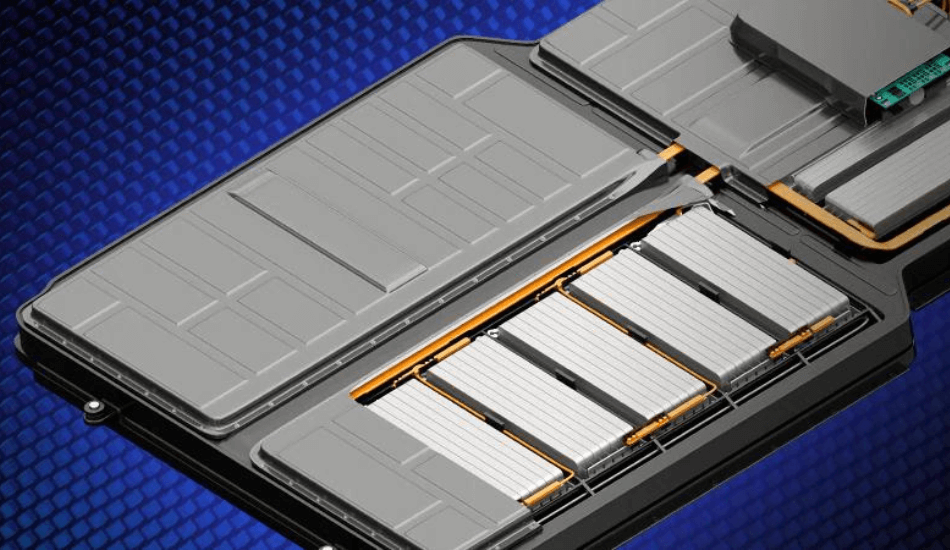

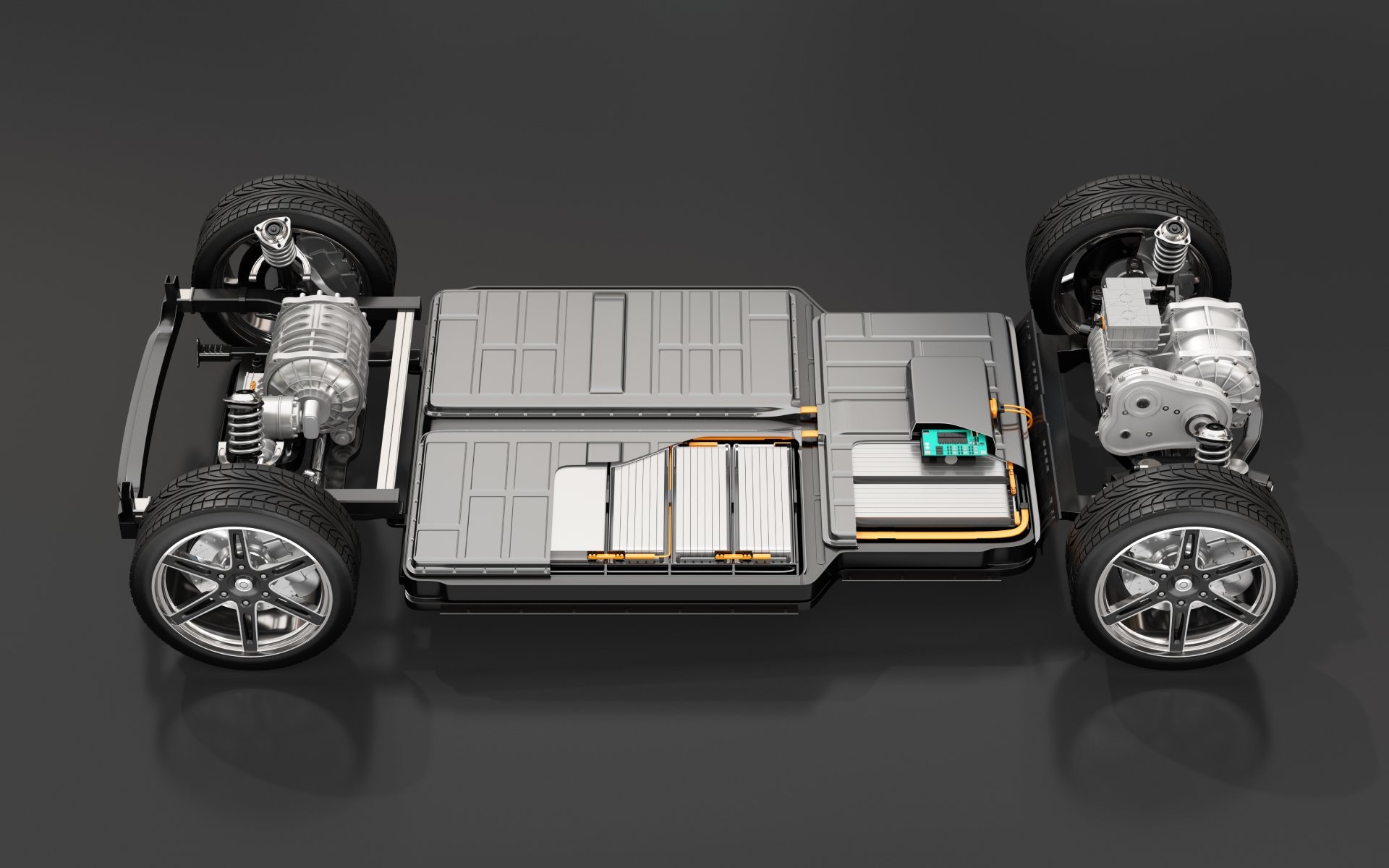

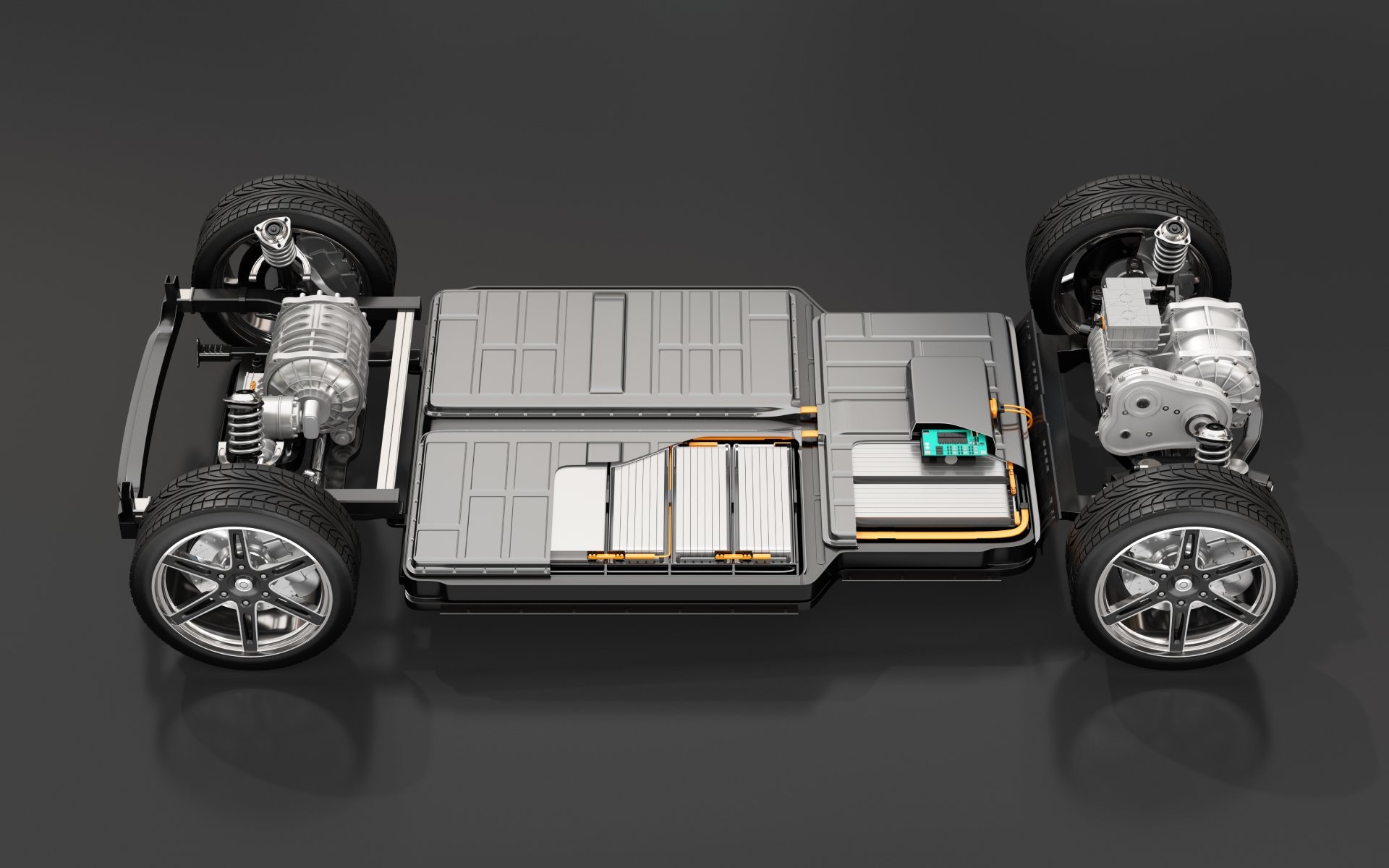

Electric vehicle batteries are made up of several components – all of which utilize die cut solutions offered by CFS. The battery cells, battery modules, battery packs and battery management system (BMS) contain one or more of the following: compression pads, thermal interface components, gaskets and seals, flame barriers, thermal runaway/anti-propagation, electrical insulation and barriers, EMI shielding and adhesive joining and bonding.

At CFS, we can work with electric vehicle manufacturers, OEMs, and suppliers to engineer custom converted and die cut solutions that meet the unique production challenges of the electric vehicle market. Read on to learn about how we can leverage our state-of-the-art facilities and materials to help with all your converted EV needs.

1. Thermal Runaway Prevention & Anti-Propagation for EV Batteries

Image battery casing Prevention and suppression of thermal runaway propagation within battery cells and modules ensures battery and EV safety. As a 3M Preferred Converter, CFS has access to the full line of barrier materials – including those for above and between cells, underlid and between modules. Many barrier materials also double as insulators as well. Inorganic paper and board materials to help address thermal runaway propagation. Additional materials we convert for anti-propagation include Formex®, Lexan and polyimide films, fibrous papers, felts, intumescent foams, and composites.

2. Thermal Management for EV Batteries

To help you achieve the higher voltages and longer range required in xEV battery designs, CFS collaborates with 3M to employ the science of thermal management. Incorporate xEV battery thermal management solutions in your designs to help extended life, range and recharge time, and enable streamlined processes and faster assembly. Die-cut thermal interface components provide heat transfer within the battery cell, pack, and module. CFS converts materials for thermal gap pads, compression pads, phase change, and graphite components to solve these issues and to increase battery life.

3. EV Die Cut Assembly Solutions

Assembly of xEV batteries is about performance – in efficiency of design and materials, in serviceability during production, and for drivers on the road. 3M bonding solutions include adhesives that deliver semi-structural and structural strength, making them ideal for use with, or in place of, mechanical fasteners. Our selection of tapes allows for excellent electrical insulation in precise locations. 3M structural adhesive tapes are excellent for applications that do not require initial adhesive cure times. Single-sided film, transfer, and double-sided tape constructions are all available as flame retardant options.

The sealing of the battery module and battery pack is critical to its operation. EV battery components within battery modules and packs are often enclosed between upper and lower housings. Seals and gaskets between these two housing elements protect sensitive components from water, dust, and air ingress. Seals also assure any dangerous materials are contained in the event of a collision. Selected gasket and seal materials must withstand extreme temperatures and are often required to be UL94 V-0 rated, passing horizontal and/or vertical burn tests. Visit our die cut gaskets page to learn more.

Compression pads and spacers are also vital components in EV battery design. They help hold the battery cells firmly in place while allowing for expansion and contraction during operation. It is essential for compression pads and spacers to be firm enough to provide adequate support and maintain compression, ensuring the longevity and stability of the battery. Designed for cushioning between cells in electrical vehicles, microcellular polyurethane cushioning foams are compression tested and can deliver consistent, moderate pressure as battery cells swell and contract during charging cycles. At the cell level, controlled compression helps reduce the negative performance impact associated with high, and uneven, pressure distribution.

4. EMI Shielding

Based on decades of developing electrically conductive solutions for consumer electronics, industrial and avionics, EMI grounding and shielding tapes from 3M are engineered to withstand a variety of factors – temperature extremes, humidity, shock, vibration and more – that are typical in electric vehicle battery systems. They provide ideal combinations of adhesion and conductivity for the long-term management of EMI/RFI, helping keep EV battery systems functioning without issues throughout the life of the vehicle.

EMI shielding and protection from 3M focuses on the development of electrically conductive adhesive transfer tapes (ECATTs), metal foil tapes and metallized fabric shielding tapes for electric vehicle battery systems. Many of these materials are designed specifically to block electromagnetic interference (EMI) across a wide range of frequencies. They perform consistently even in harsh environments, keep your battery components operating as designed, and assist with regulatory compliance requirements.

3M grounding and shielding tapes feature pressure-sensitive acrylic and silicone adhesives which serve multiple global markets including electronics and automotive. They are specially engineered with conductive particle fillers for low and stable contact resistance, uniform conductivity and maintaining adhesion in harsh environments. Electrically conductive foil and fabric tapes feature durable copper or aluminum metal foil or metallized polyester fabric carriers. 3M ECATTs, electrically conductive foil tapes and fabric tapes are suitable for xEV battery module and cooling plate grounding, battery cover grounding and shielding, battery management system (BMS) grounding and shielding and other EV battery applications. ECATTs are available at varying adhesion strengths, including high adhesion for production processes requiring holding strength and standard adhesion to enable easier rework during assembly. Electrically conductive adhesive transfer tapes are available with different adhesion levels on each side. Easy-release or tight-release film liners allow for staged assembly, and are easily removed using automated equipment.