Die Cutting Equipment at CFS

CFS can achieve tolerances as tight as +/- 0.002" when utilizing our Delta ModTech rotary laser cutter. We manufacture using state of the art equipment that can achieve tolerances of +/-0.005" including our Delta ModTech precision rotary presses, the Preco automated flatbed die cutting machine and our digital/dieless knife cutting machines. Each process has specific advantages - dictated by volume, tolerance and material type. CFS has product and design engineers on site to make sure the best process is utilized. Laser die cutting technology can be leveraged to produce rapid prototypes and production die cuts with extreme precision and efficiency while eliminating hard tooling costs. Unlike traditional die cutting methods, the laser can create tricky patterns and fine details which are otherwise impossible. This highly repeatable method enables the smallest holes, slots and perforations to be cut with perfection to your exact specifications. Digital knife cutting applications are numerous and can be used with a large variety of materials, including for custom gasket manufacturing. Perfect for projects where aesthetics are important, this process does not cause concavity and produces clean edges. Dieless knife cutting provides efficient use of materials as well as extraordinary precision and yield. Since there are no hard tooling fees, small production runs are cost effective.

Precision Die Cutting Services from CFS

CFS can achieve tolerances as tight as +/- 0.002" when utilizing our laser rotary die cutting machine. We have a number of state of the art technologies that can achieve tolerances of +/-0.005" including our Delta ModTech precision rotary presses, the Preco automated flatbed die cutting machine and our digital/dieless knife cutting machines. Each process has specific advantages - dictated by volume, tolerance and material type. CFS has product and design engineers on site to make sure the best process is utilized.

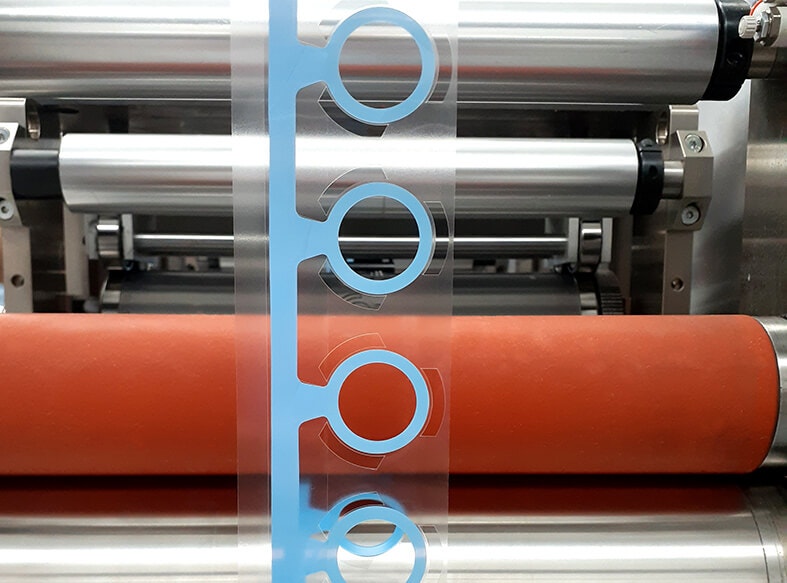

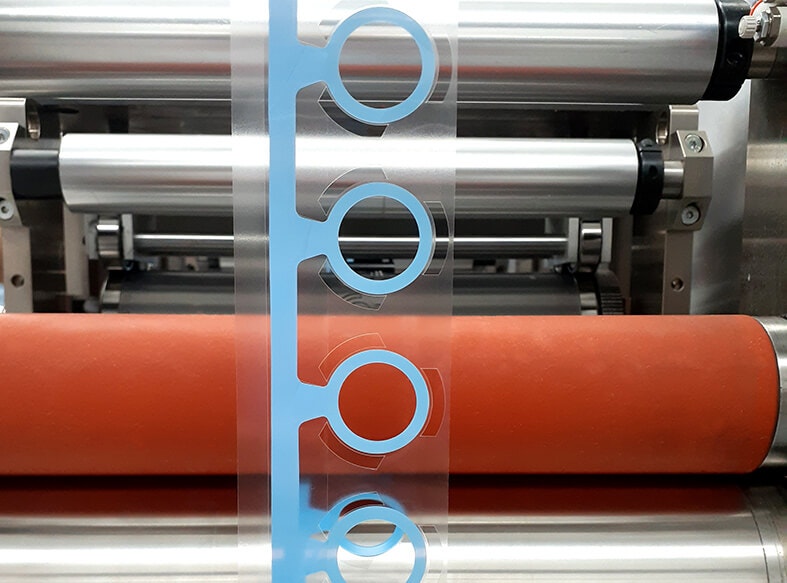

What are the benefits of using a Delta ModTech Crusader for custom converting?

The die-cutting process can only be as precise as the equipment that makes them. Since there is a separate servo motor at each station, the die cut modules can be adjusted independently of each other, allowing the cut to be changed quickly. This allows the machine to make precise cuts even when the eyemarks are inconsistent.

Individual servo controls at each die station also allow for another critical factor in web converting - precise tension control. Each die, nip or print station can be set at a different speed ratio to allow you to create tension zones with the press of a button. The PCAM (Position Cam) causes the axis to travel at different speeds throughout its rotation. PCAMing is used to make different length parts (longer or shorter) with the same tooling.

Complex and tight tolerance die cut parts require exceptional registration. The registration software is unparalleled in its ability to make corrections from incoming eyemarks to put the cut in precisely the right place automatically. Experience has proven that using both sensors and vision to register multiple die cuts provides high accuracy. Sensors are used to obtain the required speed to register each part allowing continual feedback.

State of the art technology offers precision die cutting for web widths up to 13” with tight tolerances as small as 50 microns. Precision die cutting converting services include:

- Kiss Cutting

- Sheeting

- Butt Cuts

- Split liner

- Perforating

- Pull Tabs

- Zoned Adhesive

- Island Placement

- Kitting

- Multi-layer laminations

As a 3M™ Preferred Converter, our company has expertise with a wide variety of materials and access to the full line of 3M pressure sensitive adhesives, medical and industrial tapes. For more information on our precision die cutting services or to speak with one of our knowledgeable professionals about your requirements, please feel free to Contact Us or complete our online Request A Quote form.