Shape your success with custom rubber molding

We are a 3M Preferred Converter which puts CFS at the forefront of the metal finishing industry. Known as the go-to for challenging masking solutions, customer service is the backbone of our reputation. Chat with us for immediate assistance making your selection.

It is our experience that most customers use the correct type of masking, just in the wrong size. Our member portal membership allows access to our silicone masking tool finder and instant online die cut quoting system. These tools help walk you those selecting the right product. Contact your sales representative to request access today!

In addition to the vast selection of stock items, we can customize any tape, die cut, cap or plug. Need a size that is not listed? Custom tape and die cut sizes can often be produced within 24 hours! We can engineer custom silicone caps and plugs for your specific masking needs with rapid protypes available.

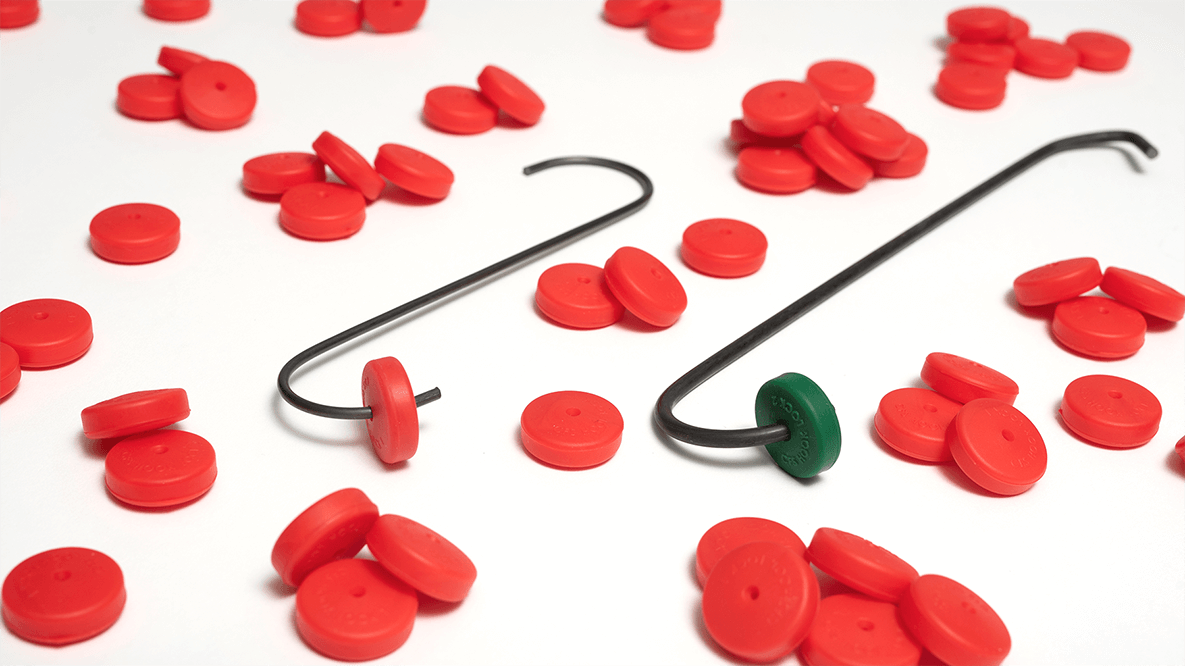

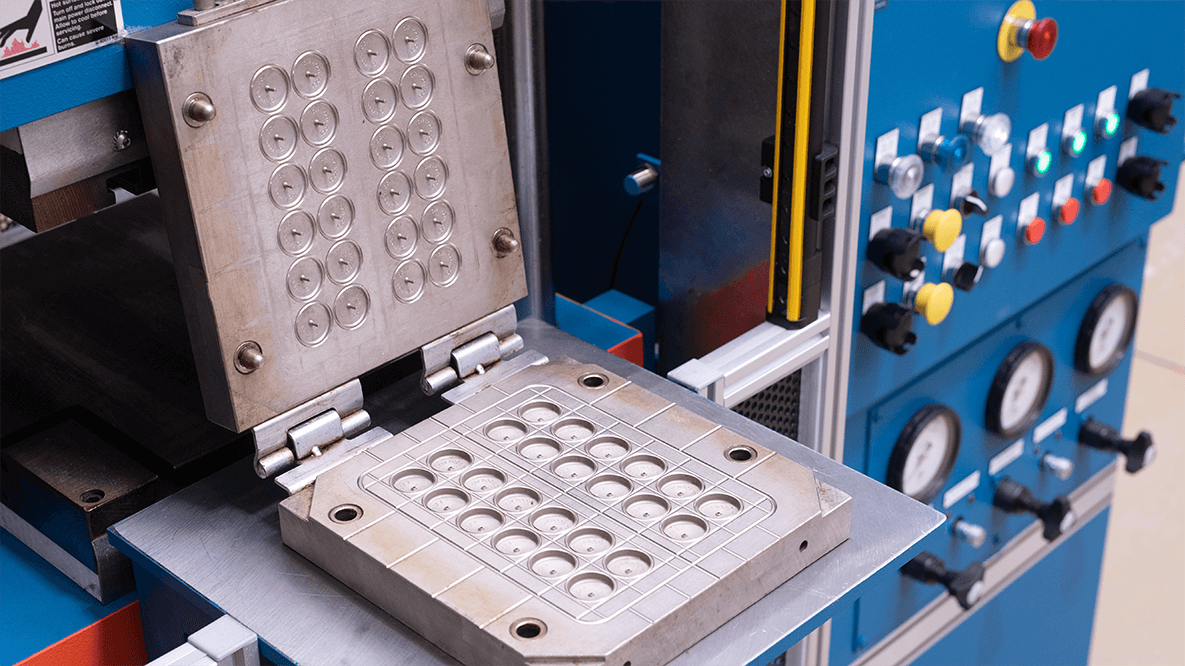

Compression Molding

Rubber compression molding forms uncured rubber into a desired shape. First, the elastomer is pre- heated until pliable and then put into an open mold cavity. Closing the mold forces the rubber to fill the cavity, where the elastomer is keep under heat and pressure until cured.

The advantages of compression molding include:

- Lower tooling costs

- Small production runs

- Suitable for larger, heavier parts

Injection Molding

Injection molding feeds uncured plastic from a hopper into heated barrel. The material is then pushed by a screw-type plunger into a heated chamber. This material flows through a gate and runner system into mold cavity. The mold remains at the proper temperature until the plastic is cured.

The advantages of rubber injection molding include:

- Quicker cycle times

- Custom shapes with little flash

- Support for wide range of durometers

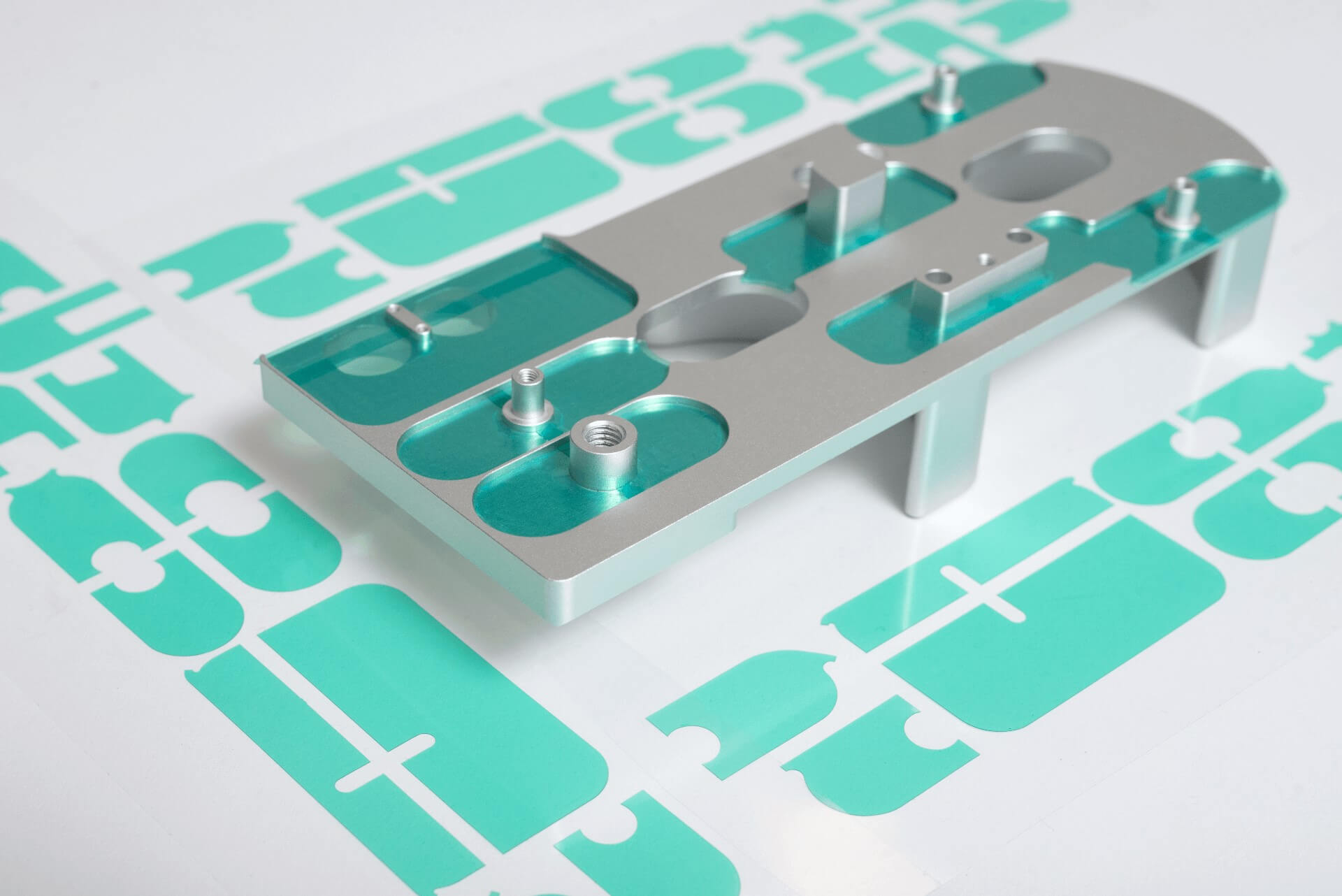

Rubber-to-Metal Bonding

Rubber to metal bonding is a means by which rubber is mechanically bonded to a metal insert during the molding process. Rubber to metal bonding is typically used for the isolation of noise and vibration in automotive and engineering applications. Rubber to metal bonded parts can be used in valve assemblies, rollers and shafts. Other applications that employ rubber to metal bonded products include mounts for motors, general rubber to metal bonded parts for the rail and transport industries and locomotive suspension parts.

The advantages of rubber-to-metal bonding include:

- Combines of the flexibility of rubber and the stability of a metal

- Finished parts are exceptionally strong and durable

- Reduce the number of parts in an assembly

Custom Extrusions from CFS

CFS offers custom rubber extrusions and extruded parts to meet your unique application. Our rubber extrusion inventory is extensive. We carry extruded parts in over 10 different shapes and in over 15 different materials. Use our extruded parts to seal out noise, control air drafts, or as decorative accessories.

Custom Profile Extrusions We Offer

- U Channels

- Tubing and Cord

- E, P & D Strips

- Bulb & Lip Seals

- Hollow Extrusions

- Sponge

Materials we can extrude and/or mold include:

- Vinyl

- Viton

- Natural Rubber

- Polyethylene

- Neoprene

- Polypropylene

- Styrene

- Delrin

- SBR

- Nylon

- EPDM

- Silicone Rubber

- Santoprene®

- Sponge

- Buna

To learn more or to speak to an experienced representative, please contact us today.

We would be happy to prepare a detailed quote for your specific needs.

Related Industies