Your Partner in Precision Electronics Die Cut Components

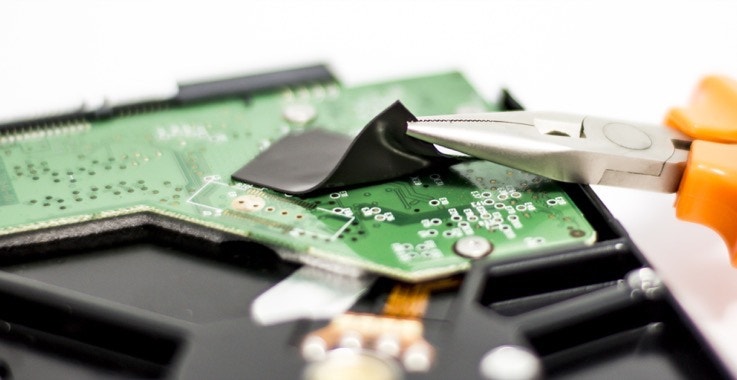

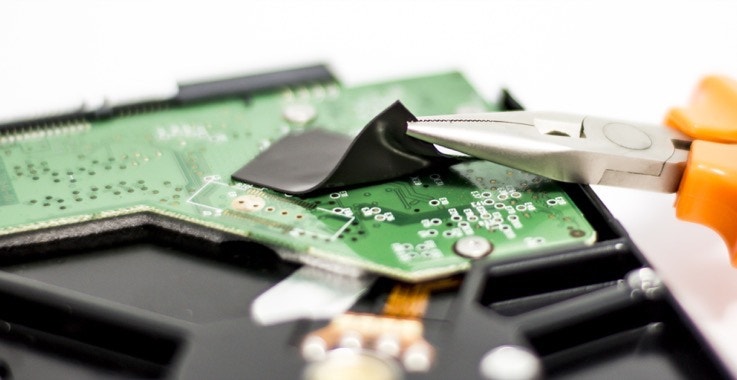

CFS has experience manufacturing precision die cut components and masking supplies for electronics. Conformal coating masking protects specific regions of PCBs and related assemblies during the film application. We have extensive experience with polyimide die cutting of dots and tape. CFS also utilizes our in-house engineering staff to create custom molded caps and boots. These can mask critical components like gold fingers during conformal coating.

Precision die cut components for electronics often include a pressure sensitive adhesive to keep the piece in place during assembly. We are experts in PSAs and as a 3M Preferred Converter we have access to their full line of products and technical expertise. The addition of clean room die cutting and packaging means even the most critical products can be produced in-house.

Our ISO 9001:2015 certification insures that the components you receive from CFS for your electrical thermal bonding, insulation and conduction needs are of the highest quality and conformance. We can also provide EMI/RFI shielding components and multi-layer laminates.

Some popular uses for CFS products in electronics manufacturing include:

- Die cuts and tapes for masking during conformal coating

- Reusable rubber masking boots, plugs and caps

- Thermal management pads

- Heat sink attachment

- Protective Films

- Electrical insulative die cuts

- Spacer and cushioning components

- EMI/RFI shielding

- Hot air leveling (HASL) masking

- Component gaskets

To accommodate the specific needs of our electronics customers, CFS offer a variety of materials that meet your rigorous requirements. Some of the most common include:

Polyimide tapes in 1 mil, 2 mil and 5 mil thickness

Copper and aluminum foil tapes

Sarcon ® thermally conductive silicone rubber

Formex ® flame retardant polypropylene electrical insulation