Digital and Dieless Knife Cutting Services from CFS

Our flash cutting machines can fabricate a part that has all the characteristics, multi levels and profiles, of a custom molded part combined with the lead time and low up-front cost of a custom die cut, while maintaining no hard tooling commitment. Our dieless solution allows for single piece sampling, rapid prototyping and large diameter parts.

Why Digital Cutting?

The ATOM Flashcut dieless knife cutting system has become the machine of choice, from small gasket converters to major manufacturers. The diversity of the ATOM Flashcut is the key factor to its success. From concept, through research and development, prototyping, multiple applications to production quantities, the final product can be quickly developed to suit your gasket cutting needs.

- Eliminates cutting dies and tooling costs

- Rapid prototyping, samples and pre-production runs

- Short and 1 off production runs are not cost prohibitive

- Reduces material waste

- Complex 3D shapes can be milled, routed, punched and cut

- Capable of kiss-cutting, engraving, plotting and 45° angle cutting

Equipment Capabilities

Custom Fabricating & Supplies has been employing flash cutting since 2011. We currently have three machines which can mill and cut parts 5’ x 10’, up to 5” in thickness. The milling capabilities of the Atom Flashcut 3015S EMHD are unparalleled. We are one of a very few companies in the US to utilize this technology.

Materials Capability of the Flash Cutting System

The dieless system is CNC based and enables CFS to manufacture OEM gaskets and component die cuts quickly and cost efficiently from a wide variety of materials including: foams (open and closed cell), rubber and its by-products, films, silicones, sponge, plastics, cloth and fabric, felts, textiles, tapes, adhesives, filtration materials, foils, fiber gasket material, insulation, cork, leather, and many other non- metallic materials from a wide variety of manufacturers.

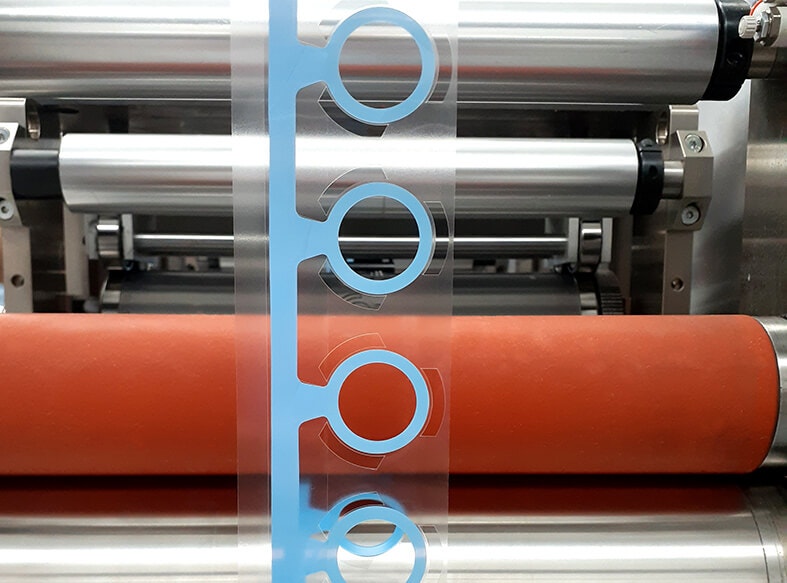

What makes a Delta Crusader the premier choice for custom converting?

Die cuts can only be as precise as the equipment that makes them. Since there is a separate servo motor at each station, the die cut modules can be adjusted independently of each other, allowing the cut to be changed quickly. This allows the machine to make precise cuts even when the eyemarks are inconsistent.

Individual servo controls at each die station also allow for another critical factor in web converting - precise tension control. Each die, nip or print station can be set at a different speed ratio to allow you to create tension zones with the press of a button. The PCAM (Position Cam) causes the axis to travel at different speeds throughout its rotation. PCAMing is used to make different length parts (longer or shorter) with the same tooling.

Complex and tight tolerance die cut parts require exceptional registration. The registration software is unparalleled in its ability to make corrections from incoming eyemarks to put the cut in precisely the right place automatically. Experience has proven that using both sensors and vision to register multiple die cuts provides high accuracy. Sensors are used to obtain the required speed to register each part allowing continual feedback.