Masking FAQs

- January 21, 2025

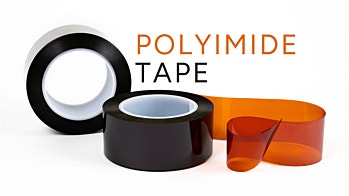

When it comes to withstanding extreme heat, few materials perform as reliably as polyimide tape. Known for its outstanding durability and versatility, polyimide tape, also known by its trade name Kapton®, is indispensable in industries like automotive, aerospace...

- December 30, 2024

Selecting the right high-temperature tape for industrial applications like powder coating, wet spray, plating, e-coating, or anodization is essential for achieving a flawless finish. The best tape isn’t just about maximum temperature resistance; it’s about choosing...

- December 06, 2024

Our latest catalog, released this month, offers a comprehensive range of converting capabilities along with our full line of industrial masking supplies, all designed to meet the diverse needs of industries such as aerospace, automotive, electronics, heavy equipment...

- November 15, 2024

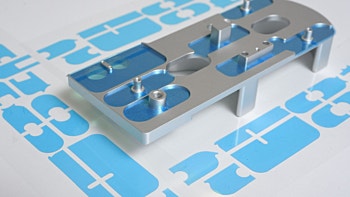

Custom masking kits are specifically designed to match the critical surfaces that need to be covered during coating, plating or wet spray applications. These templated kits ensure precise coverage, protecting areas that must remain free of coating, and improving...

- August 29, 2024

Selecting the right masking plug depends on several factors, including the product application, the size or dimensions of the area to be masked, the environment, and the material. Here are some tips to help you choose:

1. Material compatibility: Ensure the...

- February 24, 2021

Powder coating is a dry finishing process that has become extremely popular since its introduction in North America in the 1960s. Representing over 15% of the total industrial finishing market, the global powder coatings market is expected to reach $16.55B by...

- December 21, 2020

Q. We are having issues with plug loss and leakage during coating. Rework is expensive – how can we mitigate this?

A. Excellent question! There are many factors that influence plug loss or leakage. Here are some recommendations for avoiding plug loss, leakage...

- August 26, 2020

Q – We use silicone masking caps and plugs in our powder coating line. After a few uses the paint builds up and begins to flake off during the subsequent wash cycles, contaminating the finish. How can we clean these to get the most use out of them?

A – This is...

- October 01, 2019

A Guide to the Cost of Failed Masking in Finishing Processes

A rack of discards sits in the middle of the room. Shelves of streaked parts, awaiting their disposal. “What happened”, we ask? “Oh, the plugs must have leaked as they were coated”, was the reply. We...