Masking Issues

- April 24, 2025

Be sure to join us at SUR/FIN® Expo in Rosemont, IL from June 3-5. At this event we will present innovative solutions for surface finishing, including die-cut and converted flexible materials, color-coded silicone caps and plugs, and custom molded parts. Featured...

- March 18, 2025

Being a 3M Preferred Converter means belonging to an elite class of converting companies that consistently demonstrate superior quality control, manufacturing capabilities, technical expertise, and customer service. While many companies can purchase and convert...

- January 21, 2025

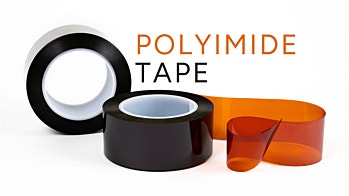

When it comes to withstanding extreme heat, few materials perform as reliably as polyimide tape. Known for its outstanding durability and versatility, polyimide tape, also known by its trade name Kapton®, is indispensable in industries like automotive, aerospace...

- November 15, 2024

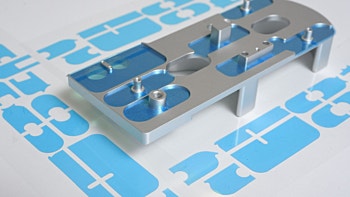

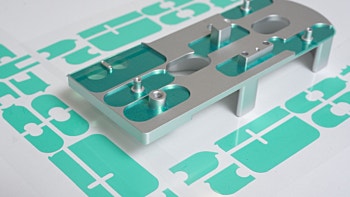

Custom masking kits are specifically designed to match the critical surfaces that need to be covered during coating, plating or wet spray applications. These templated kits ensure precise coverage, protecting areas that must remain free of coating, and improving...

- August 29, 2024

Selecting the right masking plug depends on several factors, including the product application, the size or dimensions of the area to be masked, the environment, and the material. Here are some tips to help you choose:

1. Material compatibility: Ensure the...

- December 05, 2023

Custom masking solutions, while requiring a higher up-front investment, can significantly enhance operational efficiency and long-term profitability. Many companies hesitate to transition from standard, off-the-shelf masking products due to perceived cost concerns...

- February 21, 2023

Coating small parts, whether through powder coating or electrocoating, can present unique challenges. Since each part must be individually hung for full coverage and grounding, parts can come off the hook during a wash cycle or float off during immersion. One customer...

- May 06, 2021

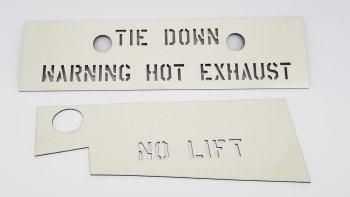

Chemical Agent Resistant Coating (CARC) is the organic topcoat used on the majority of the armed service’ combat vehicles, aircraft, ordinance and tactical equipment. Its unique formulation allows coated vehicles to be decontaminated in the event of exposure to...

- November 10, 2020

Below is an excerpt from a featured article written for pfonline.com. Read the entire editorial HERE.

What differentiates CFS as a masking products supplier is the extent to which work with finishers on finding solutions to process problems. Masks generally fail...

- March 03, 2020

Chromic acid anodization (CAA) is the one of the oldest and most widely used processes in the aerospace and metal finishing industries. Type I Chromic Acid Anodizing is an electrochemical process that creates a thin aluminum oxide film by rapidly controlling the...