Technology Solutions

- February 11, 2025

We are excited to announce our participation in The Battery Show in Atlanta. This is a prime opportunity to meet with industry leaders, explore cutting-edge technologies, and discover innovative solutions for the rapidly evolving automotive, battery, and electric...

- September 30, 2024

What is EMI? Electromagnetic interference (EMI) is an electronic emission (noise) that interferes with the performance of electronic components and systems. When the amount of noise (EMI) rises higher than the strength of the signal, this results in a low signal-to-noise...

- July 10, 2024

The word “laser” is an acronym for “Light Amplification by Stimulated Emission of Radiation”, and commonly used in industrial die cutting. From die cut thermal pads for LED lighting to EMI shielding for EV batteries, laser die cutting provides almost limitless...

- February 21, 2023

Coating small parts, whether through powder coating or electrocoating, can present unique challenges. Since each part must be individually hung for full coverage and grounding, parts can come off the hook during a wash cycle or float off during immersion. One customer...

- February 07, 2023

Christmas 2022 brought the final production machine to the floor of the Custom Fabricating & Supplies expansion (CFS, Franklin, WI) – a 50 ton compression/transfer molding press. “The past 3 years have highlighted many challenges in the supply chain. The number...

- August 09, 2021

Creating a non-adhesive "island" on a tape die cut might seem simple, but the process is highly complex. CFS recently partnered with a customer to produce a polyimide die cut that required precise non-adhesive zones. This project was completed in our ISO 7 clean...

- July 12, 2021

As a 3M™ Preferred Converter, CFS has the opportunity to work on challenging projects which require extensive knowledge of the intricacies and variables of die cutting VHB and other high-performance foam tapes. The properties of these tapes - which make them desirable...

- May 06, 2021

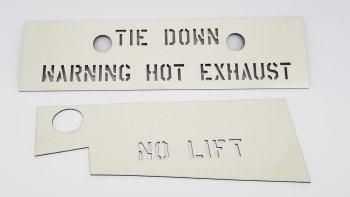

Chemical Agent Resistant Coating (CARC) is the organic topcoat used on the majority of the armed service’ combat vehicles, aircraft, ordinance and tactical equipment. Its unique formulation allows coated vehicles to be decontaminated in the event of exposure to...

- January 28, 2021

A large equipment manufacturer was struggling to trace masking issues through their paint line. They asked CFS if we would be able to produce kit die cuts with QR codes that could be scanned at each step in the paint process. With our new Domino printer installed...

- September 15, 2020

Our customers love the convenience of having 24/7 access to their account at CFS. Orders can be placed when it's convenient for YOU and are processed within 1 business day. A Fast Track account is an extension of your in-house account. While you can certainly order...