After experiencing tremendous growth in 2021 we were bursting at the seams. Navigating supply chain delays and shortages throughout the ‘22 expansion, the final machine arrived just in time for Christmas. When the dust settled we gained 32,000 square feet in our Franklin, WI location, new and renovated office space, and 6 new production machines and an expanded Houston location which tripled the size of that facility.

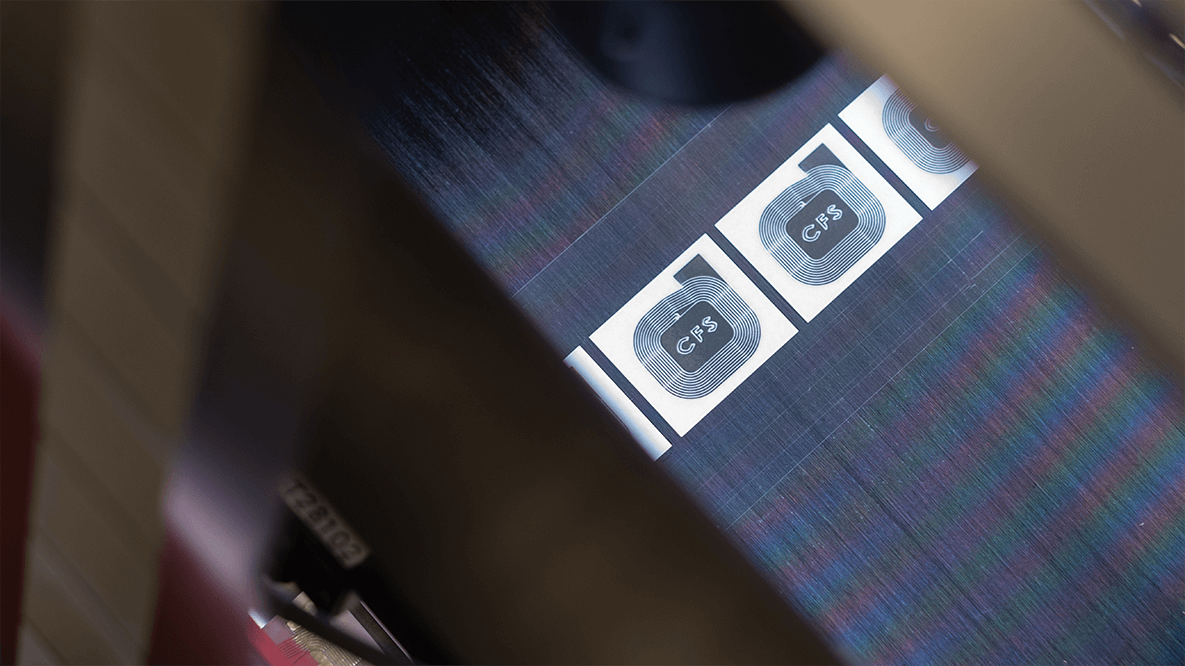

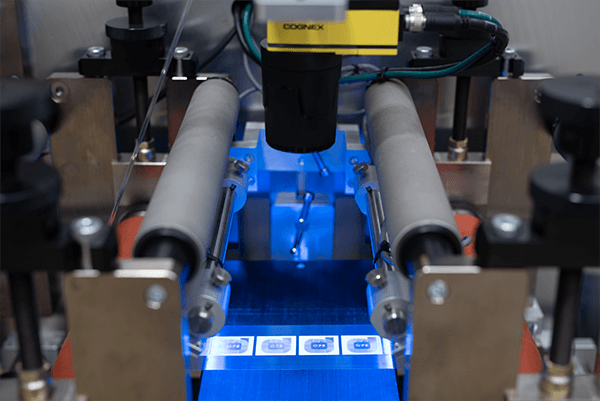

CFS is always exploring and investing in advanced technologies. The expansion provided us the space to bring on the long-awaited new flagship of our converting operations – a Delta ModTech high speed rotary press equipped with a Flex Edge® laser and MOD-Track® vision inspection system. With this system we can hold tolerances that are generally unheard of in the die cutting industry.

The final production machine to arrive was a new 50 ton compression/transfer molding press. “The past 3 years have highlighted many challenges in the supply chain. The number of requests for in-house custom silicone molding has skyrocketed. We listened,” commented Henry Asik, VP of CFS. This 50 ton press will be available for custom projects for those customers who require US silicone molding services and shorter lead times. “We have space for additional molding machines which we expect to bring on-line in the next 12-18 months,” continued Henry.

The first products we are molding in-house are our patent pending Hook Locks. Fitting over the end of a coating hook, they prevents part loss. This is also a very important safety feature, preventing parts from falling off automated overhead paint lines onto unsuspecting employees below. Designed from high temperature silicone, they can be re-used many times. Currently stocked for wire diameters of 0.062”- 0.180”, other sizes are available on request. These hook locks are suitable for use on most paint hooks types including standard S, C and V, jam hooks, spring hooks, snap hooks, crossbar hooks or any other hanging hook systems where part loss is a concern.

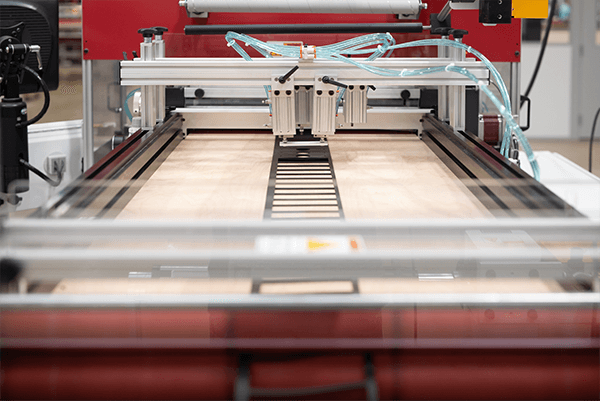

The Siat narrow web rewind slitter is a specialty machine with a very unique use. Certain tapes, like 3M 468MP (a transfer tape), are notoriously difficult to slit using standard single-knife operations. The lack of carrier material causes the adhesive to “roll” onto subsequent layers, making them challenging to unwind. The Siat can unwind the master roll, slit with razors and precisely rewind onto new cores. This process is slower than traditional methods but provides extremely precise rewind slitting.

“We look forward to hosting an open house in early summer. We will be opening our doors to our customers, vendors, suppliers for tours and demonstrations. Watch our social media platforms for more information as we get into spring,” concluded Henry.